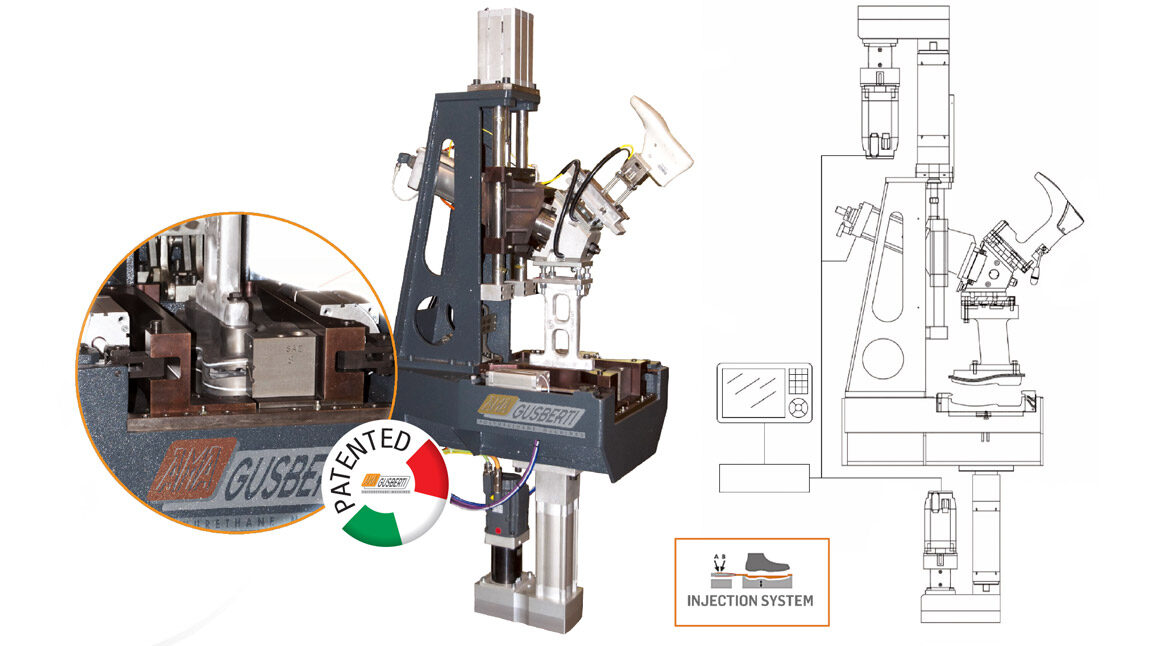

Electric injection mould holder

The new servomotor mould holder for injection control unit can operate the electric servomotor by imposing different movement speeds according to specific needs.

The speed of movement imposed on the support surface, and therefore on the lower wall of the mold, can be varied from one phase to another of the processing, but can also be varied during the same phase along the single working stroke.

This possibility allows to obtain optimal results in relation to those phenomena that are influenced by the application times of the different processing phases. Some of these phenomena are for example the evacuation of the air from the cavity of the mold, the reaction between the isocyanate and the polyol in the formation of the polyurethane, the surface cross-linking of the polyurethane, the adhesion of the polyurethane to the upper and at the tread, the formation of bubbles and gaps within the mass of polyurethane.